The Effect of Holding Time Artificial Aging on Hardness and Microstructure of Al-2024

DOI:

https://doi.org/10.47355/aset.v2i1.23Keywords:

aluminum 2024, artificial aging, hardness value, microstructureAbstract

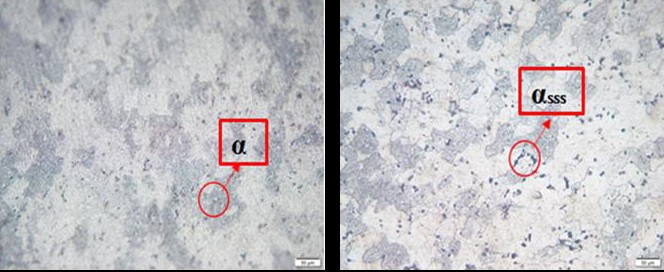

This study aims to determine the effect of holding time artificial aging on the hardness and microstructure of Al-2024. This study used a specimen in the form of Aluminum 2024 series which was heat treated at a temperature of 500°C for 60 minutes, then quenched with a cooling medium in the form of water. Subsequently, it was reheated with variations in holding time, namely 3 hours, 5 hours and 7 hours with a temperature of 190°C. Then the specimen is slowly cooled to room temperature. The results of the chemical composition test using Spectromax showed the percentage of Al was 90.6% and Cu was 5.90%. The results of the hardness test using the Rockwell Hardness Tester obtained a hardness value without heat treatment which has a hardness value of 71.4 (HRB), a hardness value after quenching of 66.9 (HRB). The highest hardness value is found in heating with a holding time variation of 5 hours with a temperature of 190°C, the hardness value is 84.6 (HRB) where the hardness value at a holding time of 5 hours has increased by 8.48% from the hardness value of the material without heat treatment. Microstructure testing showed that the Al-Cu material after the artificial aging process at a holding time of 5 hours had a precipitate phase (θ) with a higher amount and the Al-Cu grain boundaries tended to be more dense and regular. This means that the material that has been treated with artificial aging has precipitated deposits or the formation of a second phase which causes the material to be harder and have better mechanical properties.