Dr. DETERMINATION AND MODELING OF ULTIMATE TENSILE STRENGTH OF BREADFRUIT PEEL-LOW DENSITY POLYETHYLENE (BRFP-LDPE) COMPOSITE APPLYING BIGG’S EQUATION

DOI:

https://doi.org/10.47355/jaset.v4i1.61Keywords:

breadfruit peel; breadfruit peel-low density polyethylene composite; ultimate tensile strength, chemical modification; Bigg’s equation; ModelingAbstract

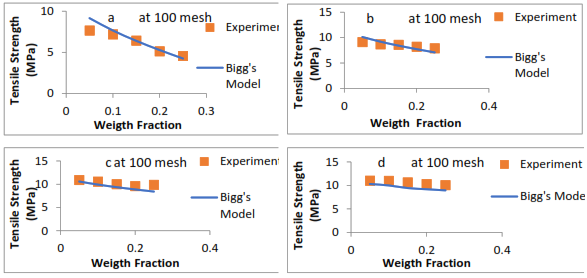

(LDPE) for breadfruit peel-low density polyethylene composite using statistical means to model ultimate tensile strength of the BRFP-LDPE composite using Bigg’s model. The breadfruit peel at fraction of 0.5-.0.25 wt when it was not modified was blended with LDPE matrix (UNT). The BRFP was later modified with NaOH (NST), NaOH+CH3COOH (AAT),, NaOH+CH3COOH+MAPE (MPT) impregnated in LDPE matrix to manufactured BRFP-LDPE composite by injection molding machine, respectively. After production, BRFP-LDPE composite was tested for the ultimate tensile strength. The results show that the Bigg’s model was able to give the prediction of the maximum tensile strength of BRFP-LDPE composite with coefficient of correlation (R2M) for the model =0.994 for UNT, NST, AAT and MPT, respectively. Also, in the same vein, the coefficient of correlation as derived from the experiments (R2) were 0.975, 0.978, 0.8 and 0.955 for the tensile strength of BRFP-LDPE composite which coincided for UNT, NST, AAT and MPT, respectively.. Finally, the relative percentage deviation modulus between experiment and Bigg’s equation (µ) <10. These statistical data seen confirmed highly prediction of ultimate tensile strength of experimental values using the Bigg”s model.

References

Aimi,N, Anuar, H., Manshor, M. R., Nazri, W. B. W., & Sapuan, S. M. (2014). Optimizing the parameters in durian skin fiber reinforced polypropylene composites by response surface methodology. Industrial Crops and Products, 54, 291–295. https://doi.org/10.1016/j.indcrop.2014.01.016

Atuanya, C. U., Government, M. R., Nwobi-Okoye, C. C., & Onukwuli, O. D. (2014). Predicting the mechanical properties of date palm wood fibre-recycled low density polyethylene composite using artificial neural network. International Journal of Mechanical and Materials Engineering, 9(1), 1–20. https://doi.org/10.1186/s40712-014-0007-6

Azeez, T. O. (2019). Thermoplastic recycling: properties, modifications, and applications. in polymer recycling (pp. 1–19). Rijeka, Croatia: InTech Open. https://doi.org/http://dx.doi.org/10.5772/intechopen.81614

Azeez, T. O., Government, R. M., Eze, I. O., & Iwuji, S. C. (2021). Modifications and Physicomechanical Behaviors of Roselle Fiber-HDPE Biocomposites for Biomedical Uses. Roselle, 89–102. https://doi.org/10.1016/b978-0-323-85213-5.00013-5

Azeez, T. O., Onukwuli, O. D., Walter, P. E., & Menkiti, M. C. (2018). Influence of chemical surface modifications on mechanical properties of combretum dolichopetalum fiber-high density polyethylene (HDPE) composites. Pakistan Journal of Scientific and Industrial Research Series A: Physical Sciences, 61A(1), 28–34.

Catto, A. L, & Santana, R. M. C. (2018). Influence of coupling agent in polyolefinic composites from post-consumer waste with Eucalyptus Grandis flour. Journal of Materials Science and Engineering B, 3(10), 641–652. https://doi.org/10.17265/2161-6221/2013.10.003

Dungani, R., Karina, M., Subyakto, Sulaeman, A., Hermawan, D., & Hadiyane, A. (2016). Agricultural waste fibers towards sustainability and advanced utilization: A review. Asian Journal of Plant Sciences, 15(1–2), 42–55. https://doi.org/10.3923/ajps.2016.42.55

l Fortunati, E., Kenny, J. M., & Torre, L. (2019). Lignocellulosic materials as reinforcements in sustainable packaging systems: Processing, properties, and applications. Biomass, Biopolymer-Based Materials, and Bioenergy: Construction, Biomedical, and Other Industrial Applications, 87–102. https://doi.org/10.1016/B978-0-08-102426-3.00005-9

Government, R. M. & Ngabea, S. A. (2023(a)).. Effect of particle size and filler content on mechanical properties of avocado wood flour-low density polyethylene composite,Journal of Applied Science, Environment and Management, 27 (10), pp. 2303-2313.

Government, R. M. & Ngabea, S. A. (2023(b)),. Comparative study on the mechanical properties of fillers-recycled low- density polyethylene for printers and car parts production, UNIZIK Journal of Engineering and Applied Sciences, 2(3), pp. 376–387.

Government, R. M. & Okeke, E.T. (2023). Elastic-characteristics of recycled low-density-polyethylene-date palmwood composite by response surface methodology optimization process for structural application. UNIZIK Journal of Engineering and Applied Sciences, 2(2), 358-368.

Government, R. M. & Okeke, E. T. .(2024). Effect of particle size on the properties of avocado pear wood fiber / low-density polyethylene composite enhanced by pretreatment. Materials Testing, 66(1), pp. 22–35.

Government, R.M., Onukwuli O.D. & Ani A.K. (2018(a)). Chemically treated avocado wood flour -LLDPE Composite. Usak University Journal of Material Sciences, 6(1–2), pp. 27–40.

Government, M. R., Onukwuli, O. D. & Odera, R. S. (2018(b)). Optimization of avocado wood flour polymer Composite. Journal of Engineering and Applied Sciences. 13: 99-109

Government, R. M., Okeke, E. T.,Thaddaeus, J., Ani, A. K., & Onukwuli, O. D. (2021(a)) Optimization of flexural and impact properties of r-LDPE-DPWF composite for printer parts production. Materials Testing, 63(4), 373-376

]Government, R. M., Ani, A. K., & Onukwuli, O. D. (2021(b)). Effect of using different chemically modified breadfruit peel fiber in the reinforcement of LDPE composite, 63, 286–292.

]Government, R. M., Ani, K. A., Azeez, T. O., & Onukwuli, D. O. (2019(a)). Effects of the chemical treatment of avocado pear wood filler on the properties of LDPE composites. Materials Testing, 61(12), 1209–1214.

l18] Government, R. M., Agu, O. S., & Olowokere, J. A. (2019(b)). The use of flame of forest pod flour in high density. Acta Technica Corviniensis – Bulletin of Engineering Tome XII | Fascicule 1 [January – March] (8889), 11–14.

Government, R.M., Omukwuli, O.D. & Azeez, T. O. (2019 (c)) . Optimization and characterization of the properties of treated avocado wood flour-linear low density polyethylene composites. Alexandria Engineering Journal, 58(3), 891–899. https://doi.org/10.1016/j.aej.2019.08.004

]Government, R. M., Okeke, E. T., Ibrahim, I. A., & Onukwuli, O. D. (2022). Modeling and simulation of tensile properties of r-LDPE/GSF composite using the response surface methododology. Materialpruefung/Materials Testing, 64(3), 446–454 https://doi.org/10.1515/mt-2021-2109.

Government, R., Olowokere, J., Odineze, C., Anidobu, C., Yerima, E., & Nnaemeka, B. (2019(d)). Influence of soaking time and sodium hydroxide concentration on the chemical composition of treated mango seed shell flour for composite application. Journal of Applied Sciences and Environmental Management, 23(1), 21-28. https://doi.org/10.4314/jasem.v23i1.3

]Harun, S., & Geok, S. K. (2016). Effect of sodium hydroxide pretreatment on rice straw composition. Indian Journal of Science and Technology, 9(21), 1-9 https://doi.org/10.17485/ijst/2016/v9i21/95245

Homkhiew, C., Ratanawilai, T., & Thongruang, W. (2014). Optimizing the formulation of polypropylene and rubberwood flour composites for moisture resistance by mixture design. Journal of Reinforced Plastics and Composites, 33(9), 810–823. https://doi.org/10.1177/0731684413518362

Kandar, M. I. M., & Akil, H. M. (2016). Application of Design of Experiment (DoE) for Parameters Optimization in Compression Moulding for Flax Reinforced Biocomposites. Procedia Chemistry, 19, 433–440. https://doi.org/10.1016/j.proche.2016.03.035

Laadila, M. A., Hegde, K., Rouissi, T., Brar, S. K., Galvez, R., Sorelli, L., Cheikh, R. B., Paiva, M., Abokitse, K. (2017). Green synthesis of novel biocomposites from treated cellulosic fibers and recycled bio-plastic polylactic acid. Journal of Cleaner Production, 164, 575–586. https://doi.org/10.1016/j.jclepro.2017.06.235

Ng, M. H., Verma, D., Sabu, T., & Goh, K. L. (2019).. Characteristics of johorean elaeis guineensis oil palm kernel shells: Elasticity, Thermal stability, and biochemical composition. Biomass, Biopolymer-Based Materials, and Bioenergy: Construction, Biomedical, and other Industrial Applications. Elsevier Ltd. https://doi.org/10.1016/B978-0-08-102426-3.00004-7

Obasi, Henry C. (2015). Peanut husk filled polyethylene composites: Effects of filler content and compatibilizer on properties. Journal of Polymers, 2015, 1–9. https://doi.org/10.1155/2015/189289

Onuegbu, G. C., Obasi, C. H., & Onuoha, F. N. (2014). Tensile behaviour of cocoa pod filled polypropylene composites. Asian Journal of Basic and Applied Sciences, 1(2), 1–7. Retrieved from www.multidisciplinaryjournals.com

Orji, B. O., & McDonald, A. G. (2020). Evaluation of the mechanical, thermal and rheological properties of recycled polyolefins rice-hull composites. Materials, 13(3). https://doi.org/10.3390/ma13030667

Peng Chang, B., Md Akil, H., Bt Nasir, R., & Khan, A. (2015). Optimization on wear performance of UHMWPE composites using response surface methodology. Tribology International, 88, 252–262. https://doi.org/10.1016/j.triboint.2015.03.028

Rajak, D. K., Pagar, D. D., Menezes, P. L., & Linul, E. (2019).. Fiber-reinforced polymer composites: Manufacturing, properties, and applications. Polymers, 11(10). https://doi.org/10.3390/polym11101667

Rashid, B., Leman, Z., Jawaid, M., Ghazali, M. J., & Ishak, M. R. (2016). The mechanical performance of sugar palm fibres (ijuk) reinforced phenolic composites. International Journal of Precision Engineering and Manufacturing, 17(8), 1001–1008. https://doi.org/10.1007/s12541-016-0122-9

Rostamiyan, Y., Hamed Mashhadzadeh, A., & SalmanKhani, A. (2014(a)). Optimization of mechanical properties of epoxy-based hybrid nanocomposite: Effect of using nano silica and high-impact polystyrene by mixture design [approach. Materials and Design, 56, 1068–1077. https://doi.org/10.1016/j.matdes.2013.11.060

Rostamiyan, Y, Fereidoon, A., Ghalebahman, A. G., Mashhadzadeh, A. H., & Salmankhani, A. (2014(b)). Experimental study and optimization of damping properties of epoxy-based nanocomposite : Effect of using nanosilica and high-impact polystyrene by mixture design approach. Journal of Materials&Design. https://doi.org/10.1016/j.matdes.2014.10.022

Rostamiyan, Yasser, Fereidoon, A., Mashhadzadeh, A. H., Ashtiyani, M. R., & Salmankhani, A. (2015). Using response surface methodology for modeling and optimizing tensile and impact strength properties of fiber orientated quaternary hybrid nano composite. Composites Part B: Engineering, 69, 304–316. https://doi.org/10.1016/j.compositesb.2014.09.031

Sood, M., & Dwivedi, G. (2018). Effect of fiber treatment on flexural properties of natural fiber reinforced composites: A review. Egyptian Journal of Petroleum, 27(4), 775–783. https://doi.org/10.1016/j.ejpe.2017.11.005

Tisserat, B., Reifschneider, L., Grewell, D., & Srinivasan, G. (2014). Effect of particle size, coupling agent and DDGS additions on Paulownia wood polypropylene composites. Journal of Reinforced Plastics and Composites, 33(14), 1279–1293. https://doi.org/10.1177/0731684414521886

Turku, I., Kärki, T., & Puurtinen, A. (2018). Durability of wood plastic composites manufactured from recycled plastic. Heliyon, 4(3), 1–20. https://doi.org/10.1016/j.heliyon.2018.e00559

Zakaria, M. S., Ghazali, C. M. R., Hussin, K., Wahab, M. K. A., Halim, K. A. A., & Yevon, L. (2018). Characteristic and morphology of palm waste filled thermoplastic composites. Solid State Phenomena, 280 SSP, 415–421. https://doi.org/10.4028/www.scientific.net/SSP.280.415

Adedayo, S.M., & Onitiri, M.A (2012a). Mechanical properties of iron ore tailings filled- polypropylene composites. Journal of Minerals and Materials Characterization and Engineering, 11, 671-678.

Adedayo, S.M., & Onitiri, M.A. (2012b). Tensile properties of iron ore tailing filled epoxy composites. The Western Indian Journal of Engineering, 35(1), 51-59.

Fuad, A M.Y., Ismail, Z., Mansor M.S., Ishak, Z.A.M., & Omar, A.K.M. (1995). Mechanical properties of rice husk ash/polypropylene composites. Polymer Journal, 27 (10), 1001-1015.

Wang, J. (2003). High-temperature deformation of Al2O3/Y-TZP particle composites and particulate laminates, Ph.D. Thesis, University of Texas, Austin.

Government, RM (2019(e)). The comparative studies on the use of some agricultural wastes as fillers for polyethylene composites. Nnamdi Azikiwe University: PhD Thesis, Unpublished.

Bigg, D.M. (1979). Mechanical thermal and electrical properties of metal fiber-filled polymer composites. Polymer Engineering and Science, 10 (1), 1188-1192.

Lomauro, C. J., Bakshi, A. S., & Labuza, T. P. (1985b). Evaluation of food moisture isotherm equations. Part 1: Milk, coffe, tea, nuts, oil seeds, spices and starchy food. Lebensm Wiss Technology, 18(2), 118-124.

Lomauro C.J., Bakshi A.S. & Labuza, T.P. (1985a). Evaluation of food moisture isotherm equations. Part 1:Fruit, vegetable and meat product. Lebensm Wiss Technology, 18 (2), 111-117

. Geneturk, M.B., Bakshi, A.S., Hong, Y.C & Labuza T.P.(1986). Moisture transfer properties of wild rice. Journal of Food Processing Engineering, 8(4), 243-261.

ASTM, (1990). Annual book of ASTM standard, Vol.8.Philadelphia, PA; American Society for Testing and Materials.