The effect of variations of V-seam root face on Shielded Metal Arc Welding (SMAW) on the mechanical properties of AISI 1045 medium carbon steel

DOI:

https://doi.org/10.47355/jaset.v3i2.62Keywords:

AISI 1045 steel, SMAW welding, weld defect, mechanical propertiesAbstract

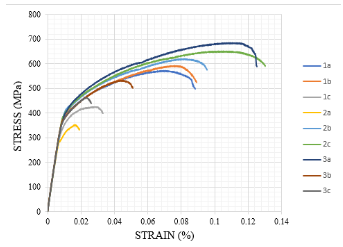

Steel is an alloy primarily composed of iron (Fe) with carbon (C) as its main alloying element. Medium carbon steel, a commonly used material in the automotive industry, is known for its strength and durability. The Shielded Metal Arc Welding (SMAW) process is widely employed to join metal parts by heating and pressing them together, using a coated electrode to protect the welding arc from oxidation. One key parameter in SMAW is the root face size, as it influences the amount of filler metal in the groove area, ultimately affecting the mechanical properties of the weld. This study investigates the impact of varying root face sizes on the mechanical properties of AISI 1045 medium carbon steel. Results from the impact test show a value of 0.772 Joules, indicating a notable correlation between root face size and mechanical performance. The tensile test results reveal that larger root face sizes reduce the filler metal qu Zulmiftahantity, resulting in higher tensile strength, as AISI 1045 steel exhibits greater tensile strength than the E7016 electrode. The highest average tensile strength, recorded at a 3 mm root face, was 559.05 MPa. Visual inspections revealed several welding defects, including spatter, porosity, start-stop marks, and pinholes.

References

R. Wahyudi, Nurdin and Saifuddin, "Analysis of the Effect of Electrode Type on SMAW Welding, Low Carbon Steel and Medium Carbon Steel Joining to Tensile Strength", Journal of Welding Technology, Vol. 1, No. 2, 2019.

Y. Miranda and AM Made, "Analysis of Temperature Differences in S355J Low Carbon Steel Materials Against Distortion in SMAW Welding", JOURNAL VISITOR, Vol. 9, No. 1, 2018.

M. Sobirin, H. Purwanto and I. Syafa'at, “Current Analysis of Variations in SMAW DC Welding Tensile Stress, Hardness, Microstructure in Low Carbon Steel”, MOMENTUM, Vol. 15, No. 2, 2019.

H. Wiryosumarto and T. Okumura, “Metal Welding Technology”, 8th Printing Book, PT Pradnya Paramita, 2000.

Tarkono, GP Siahaan and Zulhanif, “Study of Using Different Types of Welding Electrodes on Mechanical Properties of SMAW Welding of AISI 1045 Steel”, Mechanical Journal, Vol. 3, No. 2, 2012.

E. Fernando, "The Effect of Variations in Strong Welding Current SMAW (Shielded Metal Arc Welding) on Tensile Strength and Microstructure of AISI 1045 Steel Welded Connections Using E6013 Electrodes", Thesis, Department of Mechanical Engineering, University of North Sumatra, Medan, 2019.

C. Olivaminilo, “Standard Test Methods for Notched Bar Impact Testing of Metallic Materials”, Book, 2019.

C. Olivaminilo, “Standard Test Methods for Tension Testing of Metallic Materials”, Book, 2019.

Herizal, Hasrin and Hanif, "Analysis of the Effect of GTAW and SMAW Processes on the Toughness of AISI 1050 Material Welding Connections", Journal of Welding Technology, Vol. 2, No.1, 2020.

A. Suhendar, Mawardi and A. Ibrahim, "The Effect of Welding Time on the Friction Welding Process on the Mechanical Properties of AISI 1045 Materials", Journal of Welding Technology, Vol. 2, No. 2, 2020.