Design and Calculation of NACA 4412 Horizontal Wind Turbine Blades with Variations in Angle of Attack Using BEM Simulation

DOI:

https://doi.org/10.47355/jaset.v4i1.74Keywords:

wind energy, wind turbines, blade element momentum, airfoil, NACA 4412Abstract

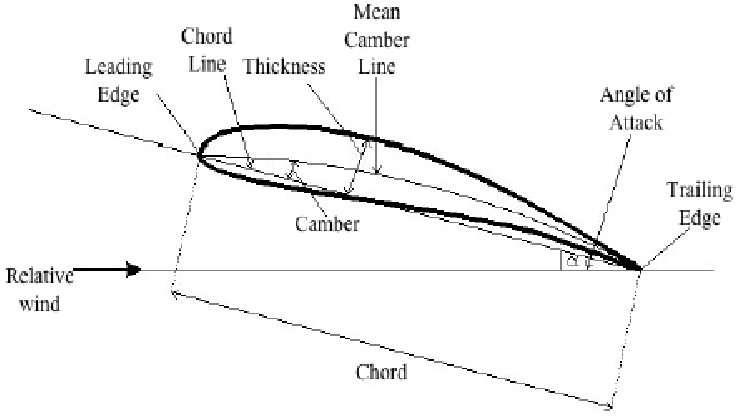

The need for electricity in Indonesia becoming increasingly part of people's needs. Fossil fuels such as oil and coal used as the main material for producing electrical energy the more limited availability, especially in its use of fossil fuels that pollute the environment. Wind energy is a renewable energy source that could potentially be developed. Wind energy is clean and does not pollute the environment in utilization into mechanical or electrical energy. The conversion of wind energy into electrical energy by converting this energy into mechanical rotation. In the wind energy utilization process made a tool to convert wind energy into electrical energy, that is wind turbines.Wind turbine or windmill is a tool for converting wind energy. Wind turbines transform kinetic energy into mechanical energy in the form of a round shaft. Shaft speed is then used to rotate the dynamo or a generator which produces electricity. The research was carried out on a horizontal axis wind turbine NACA 4412, diameter 1 m, the number of blades 3 pieces and variations in wind speed 2-8 m / s. Results showed the greatest lift (CL) at 14o angle of attack with a value of 1.583. The driving force of the smallest (CD) at an angle of attack -4o to 2o with a value of 0.008. Value CL / CD was found in the angle of attack of 6o with a value of 93.057. The maximum power generated by 484.63 Watt. Wind speed, the number of blades, angle of attack and the election of the airfoil effect on the generated power.

References

Selc, Ipek, Karamıs. 2003. A Study on Friction and Wear Behaviour of Carburized, carbonitrided and borided AISI 1020 and 5115 steels. Journal of Materials Processing Technology 141 pp. 189-196.

Beumer. 1980. Pengetahuan Bahan. Jakarta : Bhatara Karya Aksara.

DOI: 10.1080/2374068X.2020.1833605

Amanto, Hari dan Daryanto. 2003. Ilmu Bahan. Jakarta: Bumi Aksara.

Malau, Viktor. 2008. Karakterisasi Laju Keausan dan Kekerasan dari Pack Carburizing pada Baja Karbon AISI 1020.

Akay, S.K., Yazici, M., Avinic, A., 2011. The Effect of Heat Treatment on Phisical Properties of Low Carbon Steel. Proceeding of Romanian Academy Series A, Vol 10.